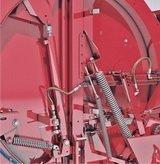

The Pelikan Max round baler will be your best assistant in the process of picking up straw swaths of natural and sow grass or hay, making and compacting round bales and winding them with twine. The machine performs perfectly each stage of its operation from gathering grass mass of any type and humidity to discharging ready-made product. Its productivity achieves 12 tons per hour. The operating width of the machine is up to 2 meters

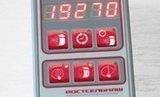

As a result of using the machine, you get a tight and even round bale. It is achieved due to the use of unique compaction control systems. The important principle of the baler operation is the saving of your resources: time, energy expenses or money. The electronic bales and operation time counting system optimizes the procedure of counting ready-made round bales. The round baler will demonstrate excellent results in all areas of lowland utilization with a field gradient not exceeding 8º. The ППР-150 round baler is designed for ideal operation.

For automated picking up and transporting bales we recommend using the self-loading bale carrier.

Optional equipment:

The Pelikan Max round baler will be your best assistant in the process of picking up straw swaths of natural and sow grass or hay, making and compacting round bales and winding them with twine. The machine performs perfectly each stage of its operation from gathering grass mass of any type and humidity to discharging ready-made product. Its productivity achieves 12 tons per hour. The operating width of the machine is up to 2 meters

As a result of using the machine, you get a tight and even round bale. It is achieved due to the use of unique compaction control systems. The important principle of the baler operation is the saving of your resources: time, energy expenses or money. The electronic bales and operation time counting system optimizes the procedure of counting ready-made round bales. The round baler will demonstrate excellent results in all areas of lowland utilization with a field gradient not exceeding 8º. The ППР-150 round baler is designed for ideal operation.

For automated picking up and transporting bales we recommend using the self-loading bale carrier.

Optional equipment:

- Centralized driving chains lubrication system

- Wide-angle drive shaft

About the availability of equipment and basic configuration check at the dealership

- Description

- Technical parameters

- Video (2)

- Ask a question

-

Quality advantages of the Pelikan Max 1500 round baler

-

Technical characteristics Model PPR-150 Performance when treating hay with a humidity level of 20…22 %, kg/s, up to 7,5 Performance per hour of productive time, t/h, up to 12 Operation speed, km/h, not more 10 Travelling speed, km/h, not more 20 Operating width, m 2,0 Weight, kg, not more 2 600 Round bale characteristics:

- diameter, mm

- width, mm

- weight, kg, not more

1 500

1 200

550Tractor PTO shaft speed, RPM 540 Consumed power, kW 30...55 Number of service staff members, persons 1 (operator) Completeness of picking up mass having a humidity level of 20…22 %, not less:

- hay

- straw

98

95Compaction density (kg/m³) of:

- prewilted grass mass having a humidity level of up to 40%,

- hay having a humidity level of 15-30%;

- straw, having a humidity level of 10-15%

150 – 250

100 – 180

50 – 120Availability factor:

- depending on operation time

- taking into account administrative time

0,98

0,97Ganging up with tractor of 1.4 drawbar category -

-

You can ask any question on technique or the work of the dealer centre.

Our skilled professionals will help you.