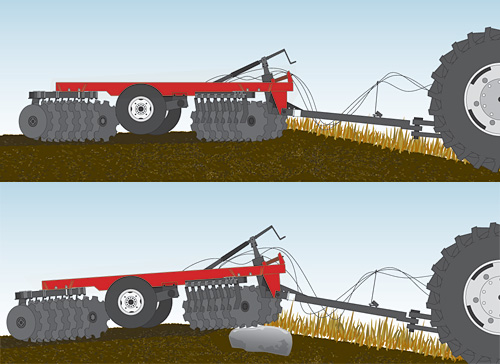

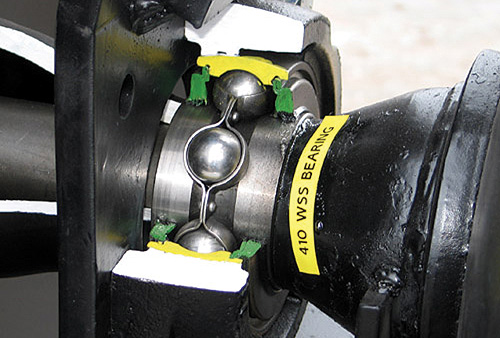

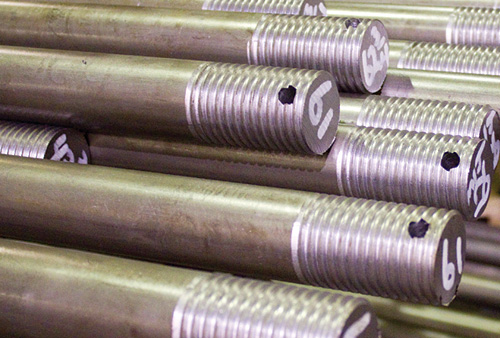

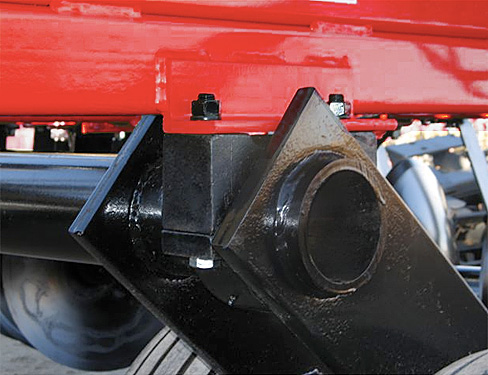

The offset disk harrows are used for main soil processing, work in fields with great amount of crop debris, fallow land (virgin soil) cultivation, fields improvement, field preparation for fallow or sowing, placement of fertilizers and deep tillage with partial backset. The advantages of the Strong and simple design, the most powerful bearings, locking steel spools between disks and long-term faultless operation, as well as matchless torque moment of disk battery bolts of 4339 Nm, all these aspects distinguish the Versatile harrows among others.

The load on 1 disk blade allows easily penetrate the soil in any conditions. The disks are of “chamomile” shape and smooth. The blade thickness comprises 9-12 mm to provide long-term and wear-free service.

Fixed angles of attack of disk batteries provide the best combination for uniform penetration into the soil and a uniform flow of crop residues.

It is aggregated with wheel and tracked tractors with engine capacity not less than 240 hp (for wheel) and 210 hp (for tracked).

The offset disk harrows are used for main soil processing, work in fields with great amount of crop debris, fallow land (virgin soil) cultivation, fields improvement, field preparation for fallow or sowing, placement of fertilizers and deep tillage with partial backset. The advantages of the Strong and simple design, the most powerful bearings, locking steel spools between disks and long-term faultless operation, as well as matchless torque moment of disk battery bolts of 4339 Nm, all these aspects distinguish the Versatile harrows among others.

The load on 1 disk blade allows easily penetrate the soil in any conditions. The disks are of “chamomile” shape and smooth. The blade thickness comprises 9-12 mm to provide long-term and wear-free service.

Fixed angles of attack of disk batteries provide the best combination for uniform penetration into the soil and a uniform flow of crop residues.

It is aggregated with wheel and tracked tractors with engine capacity not less than 240 hp (for wheel) and 210 hp (for tracked).

About the availability of equipment and basic configuration check at the dealership

- Description

- Technical parameters

- Video

- Ask a question

-

Quality advantages of Offset disk harrows DV

-

Technical specification Model DV 1000/600 DV 1500/430 Operating width, m 6,0±0,3 4,3±0,3 Efficiency per 1 hour of operating time (operating speed – 10 km/h), up to, ha/h 6,0 4,3 Processing depth, cm 7-20 7-25 Weight, no more than, kg 6500 6350 Weight per 1 meter of grip (drawbar category),kg 968 1561 Diameter x disk thickness, mm 710х9 813х12 Distance between disks, mm 305±5 356±5 Dimensions, mm, no more than:

- length

- width

- height

8000

6600

2000

7500

5062

2000Required power of tractor ICE, h.p. (minimum-maximum):

- wheel- type

- track type

240-305

210-250

350-375

300-320Draft force required on the draw-bar, h.p. (minimum-maximum) 160-200 210-350 -

-

You can ask any question on technique or the work of the dealer centre.

Our skilled professionals will help you.