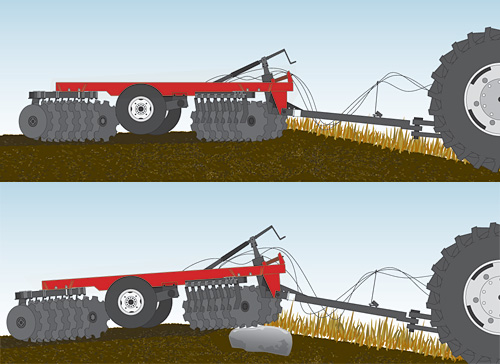

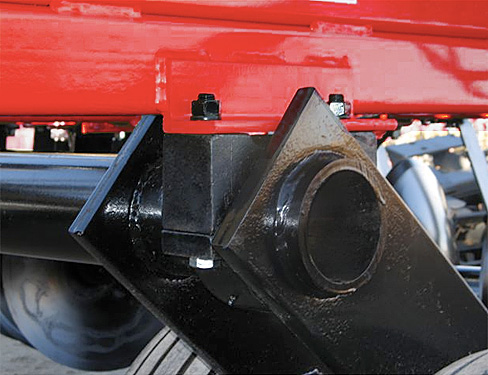

The tandem disk harrows (X-shaped or double-traced) are designed for improvement of fallow lands, field preparation for seeding, embedding of stubble remains, as well as fertilizers into soil. All tandem harrows are equipped with floating towing bar, what allows to perform much even field processing as opposed to many competitors.

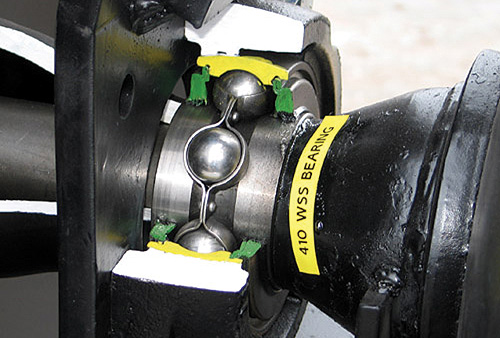

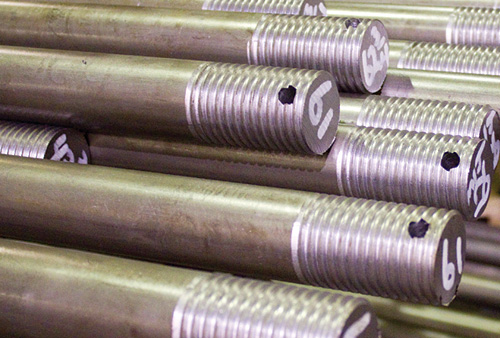

The disk batteries are tighten in plant conditions up to torque of 4339 Nm, what is impossible for many manufacturers. Steel spacers between disks stand hitting loads and prevent disks from slipping. And the Versatile bearing units are considered as the best in the industry; that’s why you will not face any problems in the field, i.e. the whole processing will be completed at term.

The load on 1 disk blade allows easily penetrate the soil in any conditions. The disks are of “chamomile” shape and smooth. The blade thickness 9 mm to provide long-term and wear-free service.

The tandem disk harrows (X-shaped or double-traced) are designed for improvement of fallow lands, field preparation for seeding, embedding of stubble remains, as well as fertilizers into soil. All tandem harrows are equipped with floating towing bar, what allows to perform much even field processing as opposed to many competitors.

The disk batteries are tighten in plant conditions up to torque of 4339 Nm, what is impossible for many manufacturers. Steel spacers between disks stand hitting loads and prevent disks from slipping. And the Versatile bearing units are considered as the best in the industry; that’s why you will not face any problems in the field, i.e. the whole processing will be completed at term.

The load on 1 disk blade allows easily penetrate the soil in any conditions. The disks are of “chamomile” shape and smooth. The blade thickness 9 mm to provide long-term and wear-free service.

About the availability of equipment and basic configuration check at the dealership

- Description

- Technical parameters

- Video

- Ask a question

-

Quality advantages of Tandem disk harrows DX

-

Technical specification Model 850/880 850/970 850/1080 Operating width, m 8,8±0,3 9,7±0,3 10,8±0,3 Efficiency per 1 hour of operating time (operating speed – 10 km/h), up to, ha/h 8,8 9,7 10,8 Processing depth, cm 7-18 Diameter х disk thickness, mm 660х9 Distance between disks, mm 267±5 Weight, no more than, kg 7000 8000 9000 Dimensions in operating position, mm, no more than:

- length

- width

- height

8000

9500

2000

8000

10500

2000

8000

11500

2000Dimensions in transportation position, mm, no more than:

- length

- width

- height

8000

3700

3710

8000

4300

3960

8000

4300

4750Required power of tractor ICE, h.p. (minimum-maximum):

- wheel-type

- track type

282-305

240-250

300-335

250-275

350-375

300-320 -

-

You can ask any question on technique or the work of the dealer centre.

Our skilled professionals will help you.