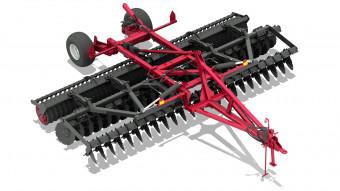

The HD-800/600 cutter harrow is designated for surface and pre-sowing soil processing, chopping stubble and crop residue, and fertilizing.

The HD 800/600 harrow is designated for use in agricultural production for stone-free soil cultivation to a depth of 12.5 cm.

The cutter harrow is designated for coupling with wheeled tractors.

About the availability of equipment and basic configuration check at the dealership

- Description

- Technical parameters

- Ask a question

-

Quality advantages of cutter harrow HD

-

Specifications Model HD-800/600 Performance in 1 hour of basic operation time at a working speed of 10 km/h, ha/h, max. 9 Operating coverage width (designed), m 6 Operating speed, km/h, up to 15 Processing depth, cm 6,0 - 12,5 Disk diameter/width, mm 560/6 Number of operating elements, pcs 49 Distance between disks in the row, mm 250±10 Number of rows in operating elements 2 Shredding of plant residues, %:

fraction size, less than 25 cm

less than 15 cm

60

80Soil crumbling %, clump size:

up to 50 mm, at least

more than 100 mm

80

not allowedTractor internal-combustion engine required power, hp 240 - 305 -

You can ask any question on technique or the work of the dealer centre.

Our skilled professionals will help you.